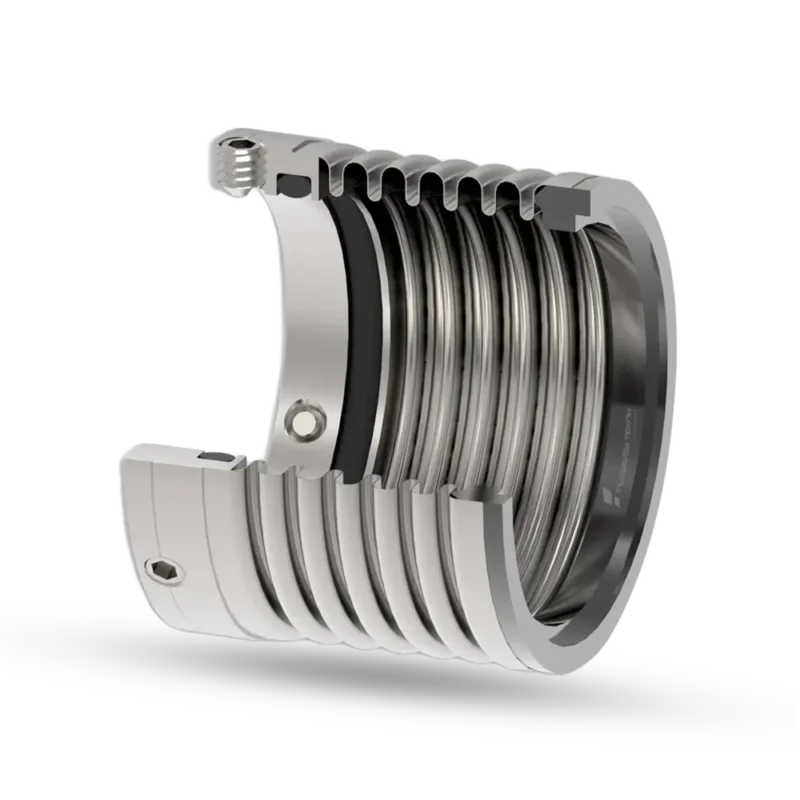

FW-SE2

Basic Features

- Structure: Double-End

- Pressure: High Pressure Mechanical Seals

- Speed: High-Speed Mechanical Seal

- Temperature: High Temperature Mechanical Seal

- Performance: Corrosion

- Standard: Specific Customization

- Model NO.: SE2

- Balance: Balanced

- Specification: Inner Diameter: 30 mm to 100 mm

Product Detailed Description

FW-SE2 Mechanical Seal for Paper-making Equipment, Alumina Plants, Flue Gas Desulphurization,Sulzer process pump, Deashing System and Slurry Pumps, Johncrane-Safematic Replacement Seal

Structural Features

double end, multi springs, balanced, independent rotary direction, still structure, pin transmission. The still springs are suitable for high operating speed. The springs are separated from the sealed mediums so they will not be jammed. Piston design allows great axial shifting. The seal is separated assembled with easy installation and reliable performance.

Industrial Standards

Specific Customization

Scopes of Application

mainly used in paper-making equipment, slurry pumps, pressure screens. flue gas desulphurization for chemical engineering, power plants, mining, oil refining, alumina plants, food processing, phamarcy, and paper making. This seal works as an alternative to similar products of Sulzer, working as Safematic replacement seals.

Operation Parameters

- Pressure: 0 ~ 2.0 MPa

- Temperature: – 20 ~ 180 ºC

- Linear Speed: 20 m/s or less

- Pressure of Cooling Water: 0.1 to 0.3 MPa

- Solid Capacity: 25% or less

Materials

- Rotary Ring Face: SiC/TC

- Stationary Ring Face: SiC/TC

- Elastomers: Viton/EPDM/Aflas/PTFE/FFKM

- Springs: SS304/SS316/HC-276

- Metal Parts: 410S/SS304/SS316/SS316L/2205/2507

Mediums

oil, water, paper pulp, cypsum slurry, acid, alkali, solvents and other solid particle and high viscosity mediums.

Customization

Changes of materials for getting other operating parameters are possible. Contact us with your requirements.