FW-5610

Basic Features

- Structure: Single End

- Pressure: High Pressure Mechanical Seals

- Speed: General Speed Mechanical Seal

- Performance: Wear

- Standard: Fits ANSI B73.1M, ISO 3069 and DIN 24960 seal chambers

- Model NO.: FW-5610 (Cartridge)

- Balance: Balanced

- Specification: Inner Diameter: 24 mm to 140mm

Product Detailed Description

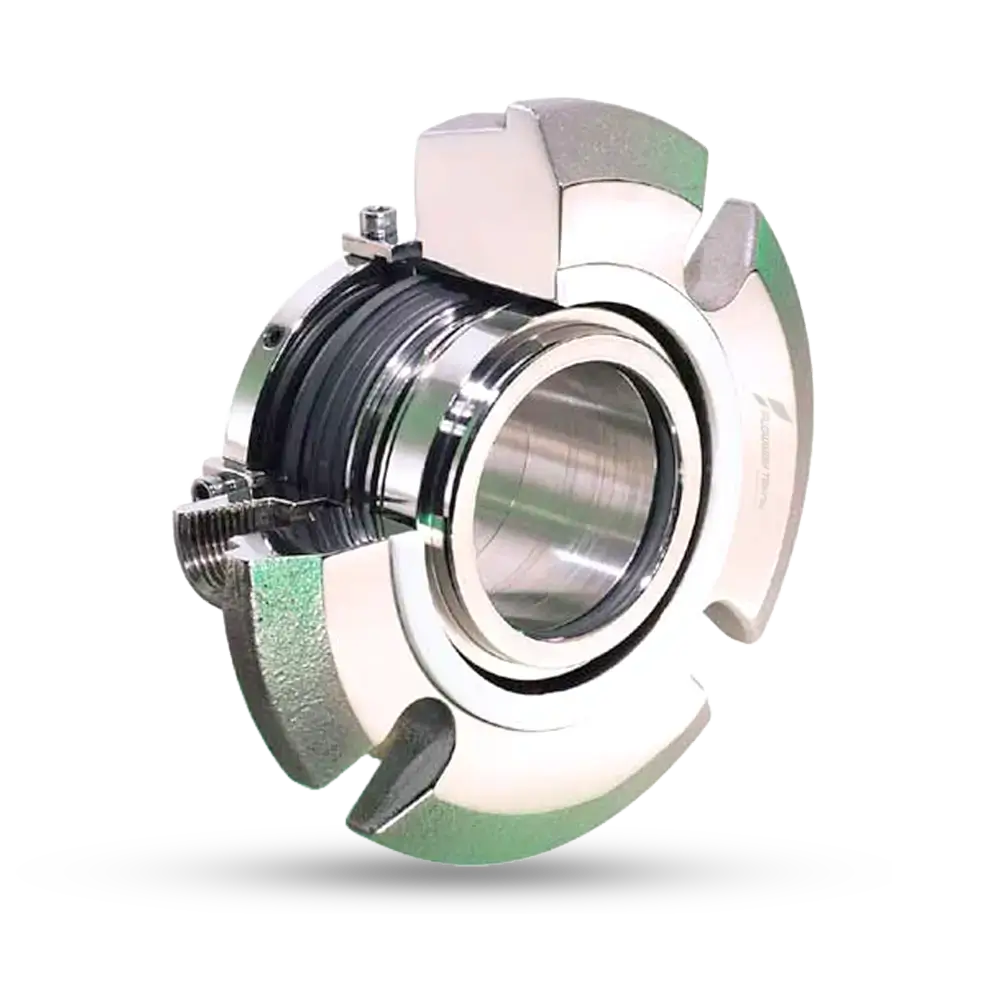

FW-5610 Cartridge Mechanical Seal

Structural Features

The 5600 Series is a modular cartridge seal family that includes interchangeable elastomer bellows, metal bellows, and elastomer O-ring pusher seal designs.

Type 5610 single seal arrangements incorporate an elastomer O-ring as the secondary sealing member

A common seal head/mating ring set, utilized throughout all versions, is reversible to allow rotating seat/mating ring or rotating seal head operation, and is interchangeable with metal bellows seal heads

Seal has quench options of carbon ring throttle bush (5610Q) and lip seal (5610L). Reversible seal head, Optimized primary ring design for greater reliability. Non-clogging wave spring outside the product

Industrial Standards

DIN24960, ISO3069, ANSI B73.1M

Scopes of Application

Widely used in water treatment, power plants, metallurgy, food processing, pharmacy, chemical engineering, fertilizer and paper making. Suitable for clear water pumps, chemical pumps, double suction pumps, paper pulp pumps, compressors and other rotary devices. Good for replacing gland packing.

Operation Parameters

- Pressure: – Up to 21 barg/300 psig (up to 75mm/3.00″) or Up to 13 barg/200 psig (75mm/3.000″ and over)

- Temperature: – 40 ~ 200 ºC

- Linear Speed: Up to 25 m/s/5000 fpm

Materials

- Rotary Ring Face: Sic/SiC/TC

- Stationary Ring Face: Car/SiC

- Elastomers: NBR/EPDM/FKM/FFKM

- Springs: SS316/HC-276

- Metal Parts: SS316/SS316L/4J42/Hastelloy

Mediums

Water, oil, acid, alkali, salt, solvents and paper pulp.

Customization

Changes of materials for getting other operating parameters are possible. Contact us with your requirements.

Category: Mechanical Seals, O-Ring Pusher