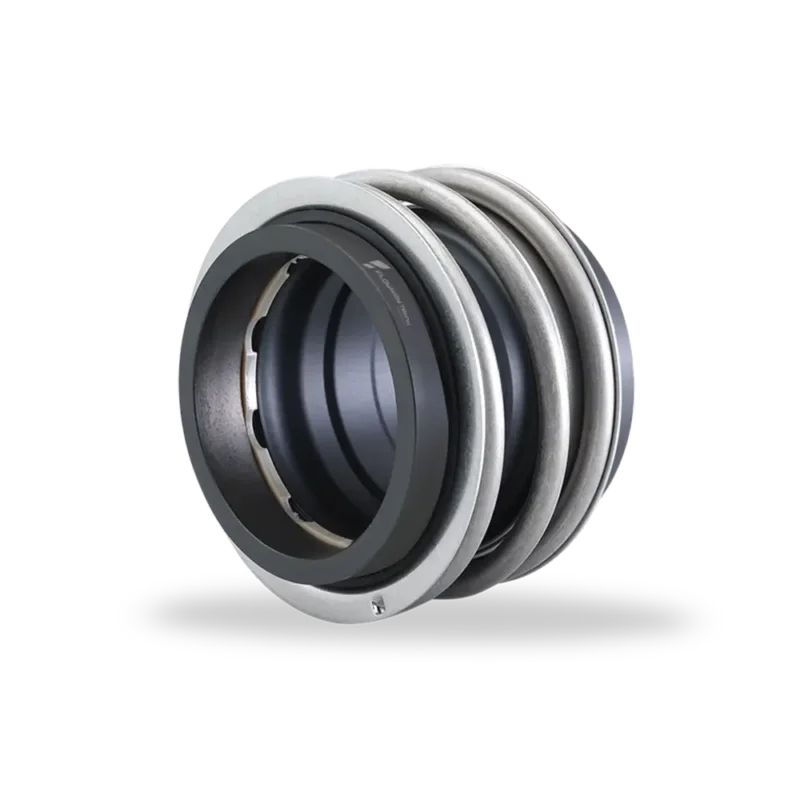

FW-HRKS

Basic Features

- Structure: Single End

- Pressure: High Pressure Mechanical Seals

- Speed: High Speed Mechanical Seal

- Temperature: Low, Medium and High Temperature Mechanical Seal

- Performance: Highly Acidic and Corrosive

- Standard: DIN24960, ISO3069, ANSI B73.1M

- Model NO.: HRKS

- Balance: Balanced

- Specification: Inner Diameter: 25 mm to 110 mm

Product Detailed Description

FW-HRKS Mechanical Seal for PFA, PTFE, PE-UHMW, PFA-P Lining Pump Used for Highly Acidic Applications and Chemical Centrifugal Pumps.

Structural Features

Single end (SN) and double end (DN), multiple springs, balanced (SN) and double balanced (DN), independent direction of rotation, still type cartridge seals. All contacting parts are non-metallic which prevents the Inboard seal parts to get corroded in all extreme acidic applications. This component has good compensation and is suitable for the situations of sudden changes of system pressure. The compensatory ring is inside the flange and the elastomer rings protect the springs at the medium side to make sure no contact between the springs and the medium, which prevents the corrosion to the springs.

Industrial Standards

DIN24960, ISO3069, ANSI B73.1M

Scopes of Application

Widely used in PFA, PTFE, PE-UHMW, PFA-P Lining Pump Used for Highly Acidic Applications in Fertilizer plants, Chemical pumps, pharmacy, chemical engineering, paper making.

Operation Parameters

- Pressure: 2.5 MPa or less

- Temperature: – 40 ~ 200 ºC

- Linear Speed: 25 m/s or less

Materials

- Rotary Ring Face: SiC/Al203

- Stationary Ring Face: Sic/SiC

- Elastomers: Viton/Aflas/FFKM

- Springs: SS316/HC-276

- Metal Parts: SS316/SS316L/Hastelloy/Duplex/Sup.Duplex

Mediums

Chemical, oil, acid, alkali, salt, solvents and paper pulp.

Customization

Changes of materials for getting other operating parameters are possible. Contact us with your requirements.

Category: Linng Pump Seal, Mechanical Seals