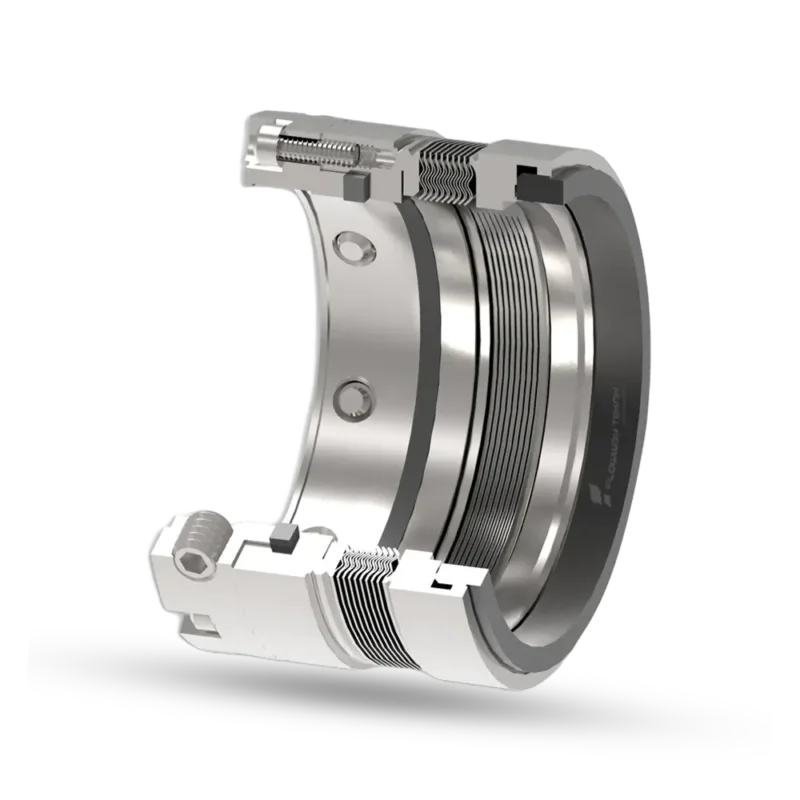

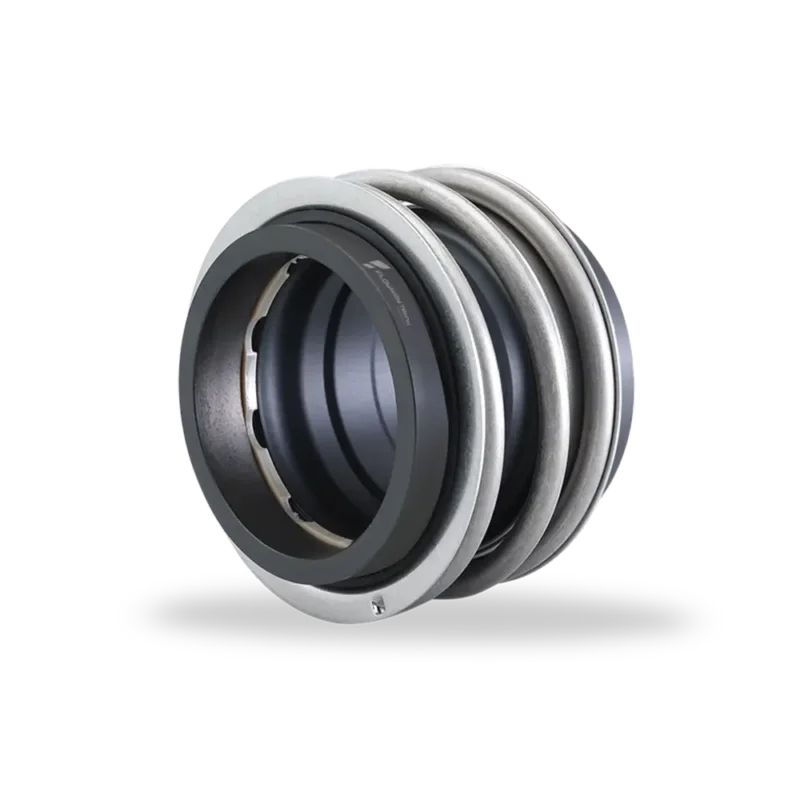

FW-SHPV Cartridge Mechanical Seal

Basic Features

- Structure: Single End

- Construction: Cartridge

- Pressure: High Pressure

- Speed: High Speed

- Temperature: Medium and High Temperature

- Performance: High Temperature and Wear

- Standard: API682

- Model NO.: SHPV

- Balance: Balanced

- Specification: Inner Diameter: 40 mm to 250 m

Product Detailed Description

FW-SHPV Cartridge Mechanical Seal for Boiler Feed Pumps, Booster Pumps.

Structural Features

Single end and multiple springs, balanced, dependent rotary direction and coil driven. The coil driven structure is simple and reliable. This seal component is easy to install and the sealing performance is stable and reliable and has a longer life time. Pumping screw/ring arrangement enhances the flow of media.

Industrial Standards

API 682 4th ed. / ISO 21049

Scopes of Application

Widely used in boiler feed pumps deployed in power plants, booster pumps and other high speed applications. It is specifically designed for boiler feed pumps, booster pumps, crude oil feed pumps, injection pumps and multiphase pumps.

Operation Parameters

- Shaft diameter: d1 = 40 … 110 (250) mm (1.57″ … 4.33 (9.84)”

- Pressure: p1 = 42 (150) bar (609 (2,175) PSI)

- Temperature : t = -40 °C … +176 (+200) °C (-40 °F … +350 (+394) °F)

- Axial movement: ±3.0 mm

- Linear Speed: 23 m/s or less

Materials

- Seal ring: Blister resistant carbon, Silicon carbide SSiC (Q1), RBSiC (Q2, Q3)

- Stationary Ring: Silicon carbide SSiC (Q1), RBSiC (Q2)

- Elastomers: EPDM (E), NBR (P), FKM (V), FFKM (K)

- Springs: Hastelloy® C-4 and C-276

- Metal Parts: CrNiMo steel 316 or equivalent

Mediums

Oil , Water, Boiler water, Crude oil Etc.

Customization

Changes of materials for getting other operating parameters are possible. Contact us with your requirements.

Category: Boiler feed pump seal, Mechanical Seals